-

Amount of weight

(load) that is to be moved.

-

Is the load moving

in a vertical or horizontal direction?

-

Is the stroke travel

unsupported or is it guided or supported in any way?

-

Is the load being

moved in only one direction or is it being moved in both

directions of the cylinder stroke? If in only in one direction,

is it on the push (extended stroke) or the pull (retracted

stroke) of the cylinder.

-

What is the

air line pressure that is driving the cylinder ?

-

Do you want the

cylinder to “pivot” when the stroke occurs or do you want it

moving in a straight line with the fixed directional mount of

the cylinder.

-

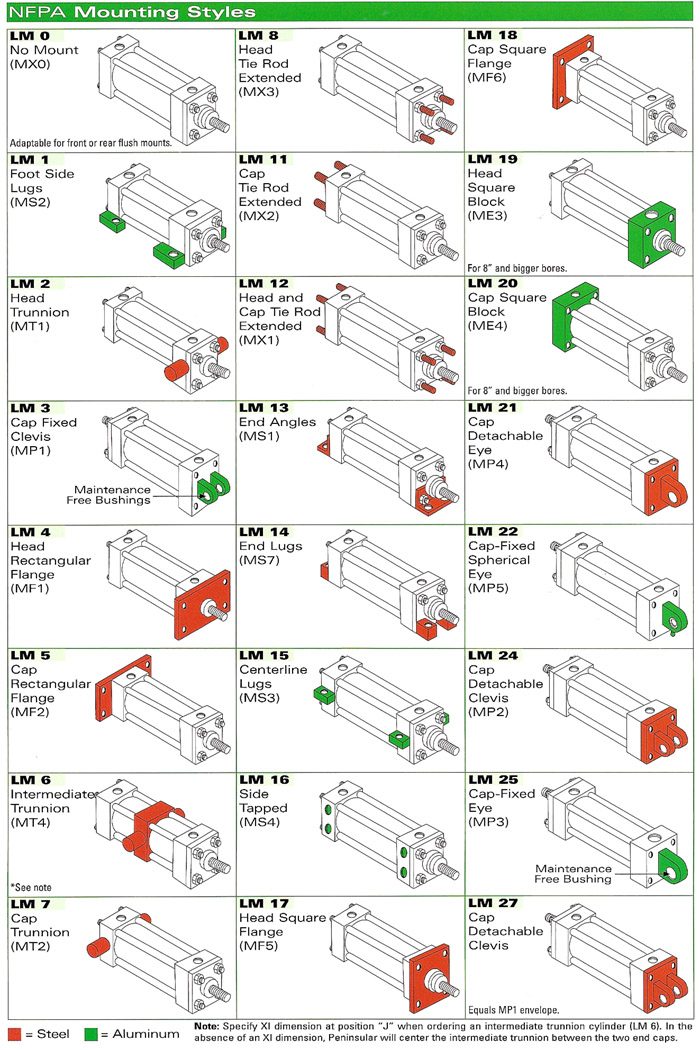

Once an intermediate

trunnion mount cylinder is ordered, it is most important to know

the XI dimension; this will tell us where to locate the center

trunnion between the front and rear cylinder end caps.

Note:

If the extended piston rod feature is selected for this mount

there will be a change to the stated XI dimension. Specify the

XI dimension under the configurable optional features section of

our configurator. If an extended piston rod or stop tube is

required, these features must be selected first before selecting

the XI dimension. Please

contact us if confusion arises because of this issue.

-

When selecting a

clevis or eye mounted cylinder (pivoting cylinder) make sure

that all clevis pins are properly greased at the time of

installation; failure to do so will lead to premature cylinder

failure. Peninsular supplies a tube of

grease with all pivot mounted cylinders such as trunnion mounts,

clevis mounts and eye mounts.

-

When selecting

lug mounted cylinders you may want to "key" the lug mounts.

These keys aid in the prevention of premature cylinder failure by

providing structural support for the cylinder tie rods and the

bolts that are used in fastening the lugs to the mounting

surface of the cylinder.

-

When selecting

flange mounted cylinders the weight of the cylinder becomes

important. You may want to consider using a “square head or cap” mount for heavier cylinders to reduce the stress

imposed upon the flange plate and the mounting screws. Note that

many cylinder manufacturers have different shapes and dimensions

for their rod cartridge retaining plates. Note that rod

cartridge retaining plates are not

specified NFPA dimensions, and as a result, careful attention

should be paid to the dimensions of the rod cartridge retaining

plate especially

if it is used in conjunction with a “pilot dimension” to mount a flange type

cylinder.

-

When selecting

head tie rod extended, or head and cap tie rod extended

cylinders careful attention should again be paid to the

dimensions of the rod cartridge if it is used as a pilot

dimension to mount extended tie rod mounted cylinders into the

tooling system. Rod cartridge dimensions are not specified by

the NFPA, and as a result, many cylinder manufactures have

different dimensions associated with their rod cartridges.